As one of the world’s leading AutoStore integrators, Swisslog is living up to its reputation, announcing 45 new projects in the last 12 months. Swisslog sold a new installation almost every week across 15 countries: Austria, Belgium, the Czech Republic, Denmark, Finland, France, Germany, Italy, Japan, Malaysia, the Netherlands, Norway, Sweden, the United Kingdom, and the United States.

Efficient small parts storage for small-mid firms

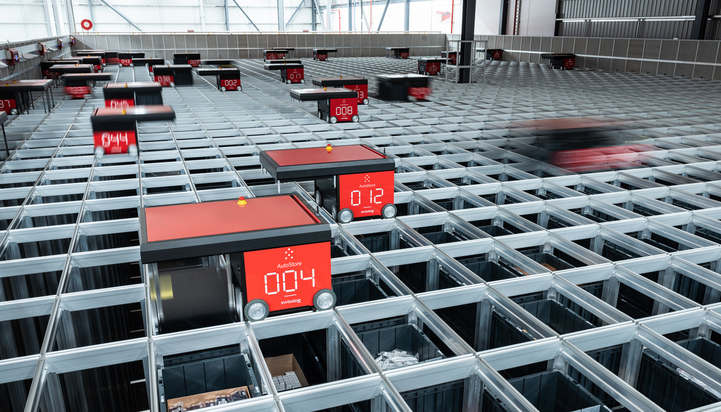

Most of the new installations have order values of 3 MEUR or below, which indicates that they are modest projects for small- or mid-size companies. For projects like this, the typical system configuration is fewer than 35,000 bins and a maximum of 35 robots, delivered with or without modular Swisslog SynQ Software, SAP EWM integration or

standardized conveyor systems. Project wins in the last 12 months include companies like Barona Logistiikka Oy, Euronics Sandman, Telmotor, and Slimpa.

For logistics service provider Barona, AutoStore and SynQ Software from Swisslog was the perfect choice for their new logistics center Avialogis in Helsinki, Finland. The first phase of the project will comprise of 28,000 bins and 10 ports, which corresponds to a little less than 1,000 square meters of space on the site and roughly estimated, closer to 200,000 small goods spaces.

The goal is for the system to be fully functional by Q2 next year. In the case of the electricals company Euronics in Estonia, 28 robots enable them to speed up deliveries to customers by 2-3 hours, or 4-8 times faster than before. Based at their central warehouse in Assaku, near Tallinn, the robots are capable of handling up to 600 bins per hour and can complete a customer’s order within 20 seconds of the transaction.

“It is great to see how happy our customers are, and that their initial considerations have been addressed. Thanks to our learnings and experiences from over AutoStore 300 projects globally, we know many ways to deal with common challenges such as permanent product availability, fast ROI, or agile project realization without interruptions,” said Markus Kirchhoff, Head of Business Unit AutoStore Europe at Swisslog.

The Italian company Telmotor supplies electrical goods and distributes quality products and brands for industrial automation. By implementing the AutoStore system, Telmotor will be able to maximize use of the space in the main warehouse, renovating it and making it fully automated. The system will be managed by 35 robots capable of

handling over 15,000 bins. Slimpa, The KONE group, global leader in the elevator sector, has entrusted Swisslog

with the warehouse automation at the 22,000 square meter Italian site. The new AutoStore warehouse, consisting of 7,000 bins handled by 14 robots for 4 picking ports, will improve the overall efficiency of storage and replenishment and intrinsically the safety of the existing traditional warehouse. Smaller AutoStore installations usually take 5-6 months from work starting on site to the system going live.

System expansion for growing businesses

In addition, Swisslog supported existing customers with system extensions, totalling 53 projects in the last 12 months. These range from a spare parts package, adding more robots, extra picking ports, or an expansion of the grid. Orders usually range between 30,000 and 700,000 EUR and return on investment is given within 1-2 years.

“Swisslog committed two years ago by establishing a dedicated Business Unit for AutoStore to meet customer expectations for the entire AutoStore portfolio and also to enable even smaller and mid-size companies to make the first steps in logistics automation”, says Markus Kirchhoff. Also, after going live Swisslog customers benefit

from more than a decade of experience in the AutoStore business and can rely on continuous support for the whole life cycle of the installation.”