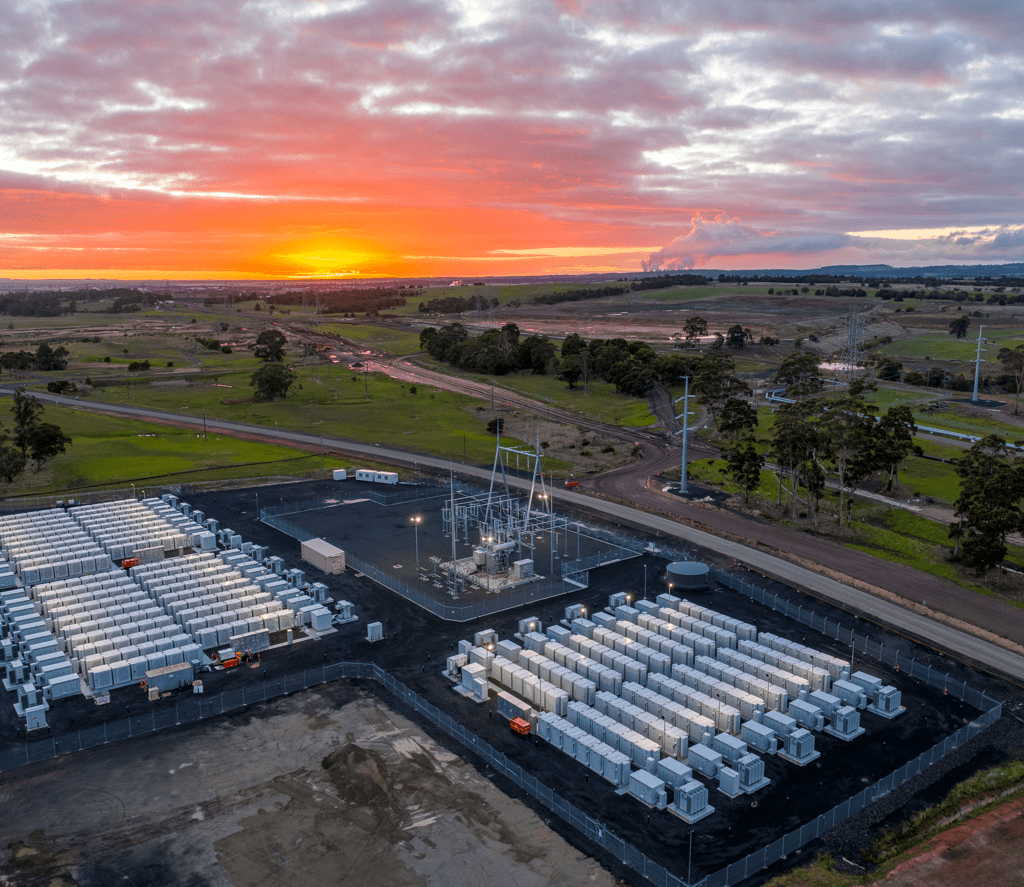

Located on the site of the former Hazelwood power plant, the Hazelwood Battery Electricity Storage System (HBESS) is a utility-scale battery of 150 MW / 150 MWh, making it ENGIE’s largest Battery Energy Storage System (BESS) anywhere in the world. The battery is made up of 342 Fluence modules, providing first-rate reliability and safety. The installed capacity will be able to store the equivalent of one hour’s electricity generated by the solar systems installed on the roofs of 30,000 homes in the state of Victoria, and to inject this power into the grid in periods of peak demand. By improving the stability of the electrical grid, HBESS will thus allow development of new renewable energy production capacity in Victoria to be stepped up to meet market demand.

Commissioning of this facility is fully in line with ENGIE’s ambition to ramp up flexibility technologies and accelerate the development of battery storage. HBESS will contribute to the Group’s target of 10 GW of installed battery capacity by 2030, announced last February.

The commissioning of HBESS is part of the site remediation of the former coal-fired power station initiated by ENGIE in 2017, in line with the Group’s strategy to withdraw from coal-fired power generation. This first reallocation of former thermal assets to renewable energy technologies in Australia is a concrete illustration of the country’s energy transition and ENGIE’s commitment to its decarbonisation pathway.

Sébastien Arbola, Executive Vice President in charge of Flex Gen & Retail activities, says: “HBESS is an illustration of ENGIE’s commitment to developing assets that provide flexibility to energy systems. Energy storage solutions such as batteries play a major role in accelerating the energy transition while guaranteeing electrical grid reliability. By storing the energy produced at times when wind and solar sources are most productive or when demand is lowest, they help to accelerate the development of renewable energies by meeting the balancing needs arising from their variable production.”